Carbon nanotubes: a matter of mats

As our demand for miniaturised electronics continues unabated, scientists are on the lookout for new materials which will let them shrink microchips down to the nano-scale. Tiny tubes of carbon are attracting a lot of attention, but more research is needed to improve their performance and find more economical methods for their mass production.

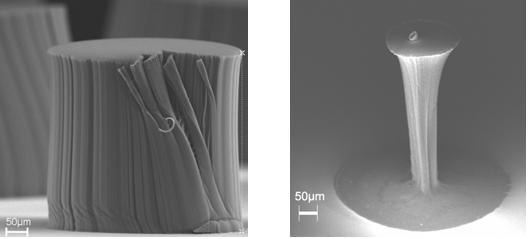

Carbon nanotubes are basically made up of flat sheets of carbon atoms rolled up into cylinders that can measure as little as just a couple of nanometres in diameter.

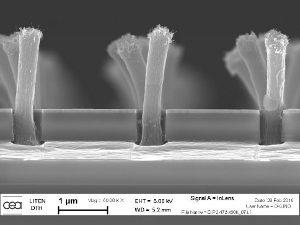

As carbon molecules, the nanotubes have unique electrical properties and scientists are getting increasingly excited about their potential to replace today’s copper interconnects in microchips, helping to shrink the size of components yet further. Carbon nanotubes can carry a much higher density of current and have better thermal conductivity than copper wires.

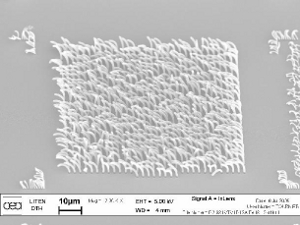

Before densification - After densification

Studies have also shown that the contact between the bottom aluminium-copper electrode and the carbon nanotube bundle is very high, making them highly efficient and producing little energy loss.

The nanotubes have just enough flexibility to physically bend and so can also function as a nano-scale electrical component called a bi-stable latch with an on and off position.

The EU-funded 'Carbon nanotubes for interconnects and switches' (Viacarbon) project has ambitions to advance nanotube production techniques so they can move out of the lab and become a stock material for the semiconductor industry.

Viacarbon has achieved the highest densities of carbon nanotube grown by any research group in the world, beating the previous record set by scientists from Fujitsu in 2009.

This story and others showcasing EU-funded 'Future and emerging technologies' will appear in issue 9 of research*eu focus, due out April 2011 on CORDIS.

Media Centre

Media Centre